Breaking down costs – EPDM Gaskets

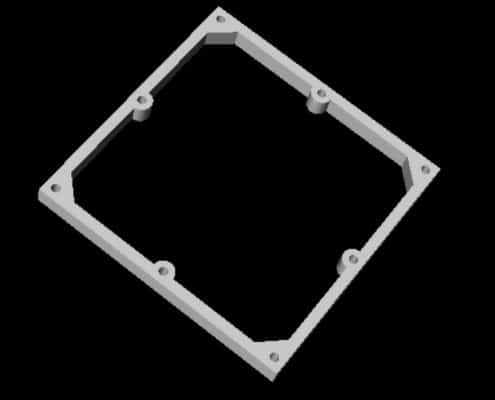

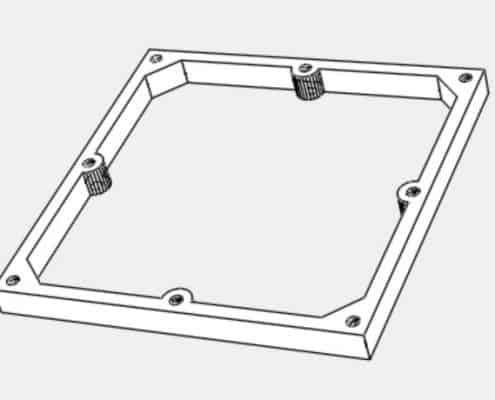

Connection Box Gasket

Today’s cost breaking exercise concerned simple 20mm thick 70sh EPDM gaskets with 8mm Ø holes and 10mm wide wall.

The customer was looking for batches of 500 to 1000 at a time and is currently having them water-jet cut.

For short quantities and testing, we can certainly make parts by water-jet – however these have their own issues:

- 20mm solid EPDM is generally only stocked in roll form – when cut this material ‘remembers’ its form and the cut parts can often be banana shaped.

- for flat moulded sheet, there is normally a minimum batch production required – in this instance, enough to cut the 1000 gaskets the customer needed!

- Water-Jet cutting is not a cheap option for higher volumes – especially at 20mm thick when abrasive cutting is best and even multi-head machines are relatively expensive.

- last but not least – the waste involved with all those centres of 20mm material would have to go for grinding, with the various handling charges involved.

So – we quoted prices water-jet cut, as the customers current supplier – but also took a step back and looked at what other methods we could use.

CNC routing the part, although much faster than water-jet, is also far too slow with a relatively high manufacturing cost, and tools tend to burn out faster than expected with rubber!

Moulding

While many would think tooling to mould relatively small parts of a ‘chunky’ moulding would be expensive, we know that in reality it is not.

With a shot weight of 285grams, we could produce a single cavity tool under £500.00 and bring the component cost down from £7.80 each to just £5.10- a saving to the customer over 1000 parts of £2200.00 a year!

So, with a little thought and a bit of a common sense, we converted the job from cutting sheet – with the inevitable waste involved, to moulding with less than 5% sprue waste – all of which is re-ground and re-processed.

A Win-Win situation for all!